INNOVATORS SINCE 2004

We are custom thick film circuit designer & builders based in Everett, WA. Founded by Ceramic Engineers and Materials Scientists with backgrounds in microelectronic and hybrid manufacturing, we have unparalleled skill and passion for Materials Quality, Engineering, Problem Solving, and Customer Success.

NEW PRODUCT DEVELOPMENT

Whether you need assistance with new product development and prototype parts, or full production runs of manufactured product, we have the experience and capabilities to support your thick film needs.

REVERSE ENGINEERING HEATERS

Thick film heaters used in the Aviation aftermarket is a growing part of our business. If you have a project that requires reverse engineering a thick film heater for Galley or Air Frame application, talk with us today.

LOW COST, HIGH PERFORMANCE

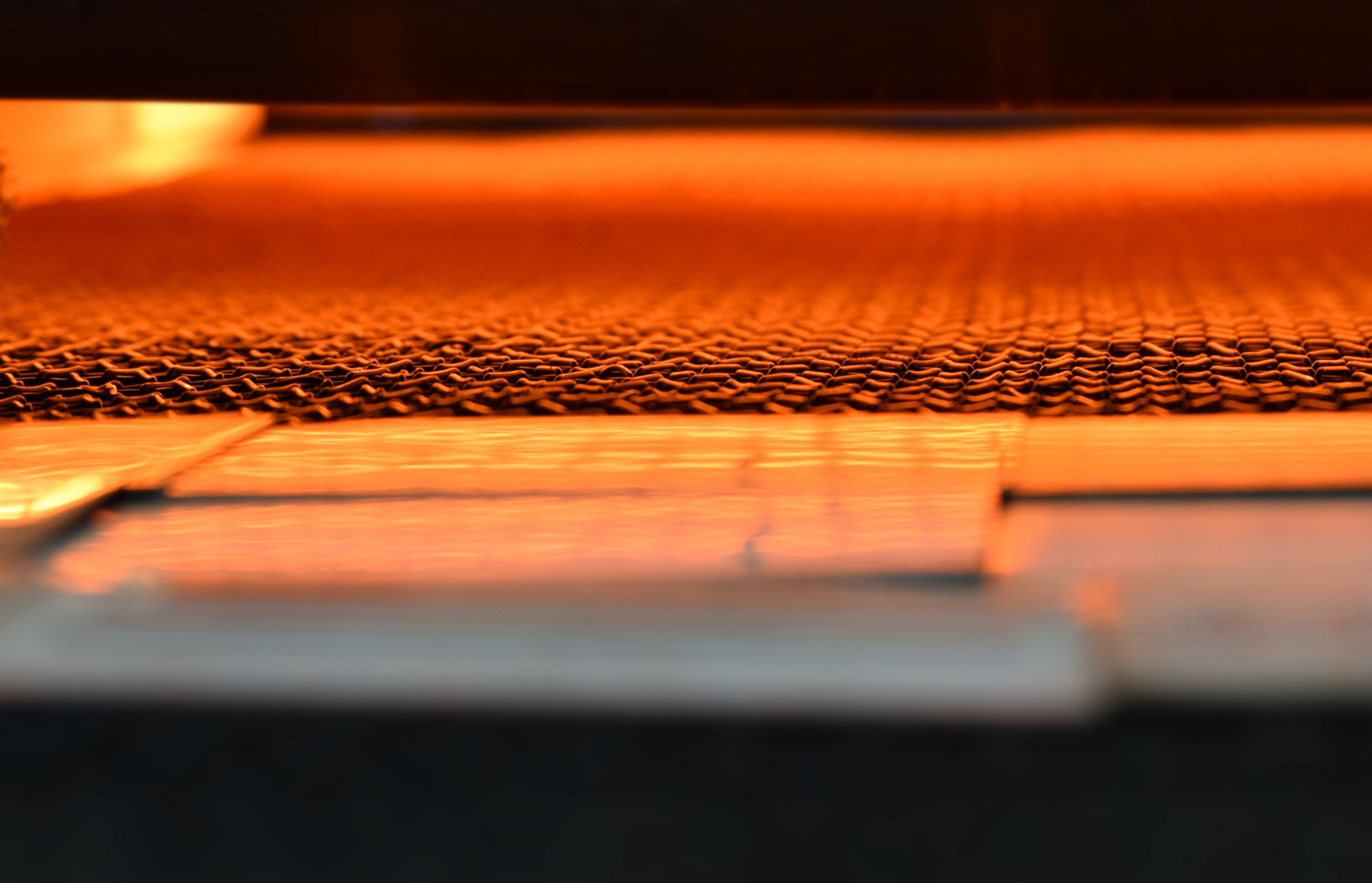

Our custom designs can be fabricated in most any two dimensional shape from a variety of materials. The low profile and high thermal coupling outperforms cartridge or wire wound heaters at equal or lower cost.

OWNER & PRESIDENT

An engineer, entrepreneur and consultant, Kirk Goldenberger built on 20+ years of experience in electronics and electro-ceramics manufacturing to found Thick Film Technologies Inc. (TFT) in 2005 in his garage. Since that time, TFT has moved twice and become an internationally known supplier of thick film products with customers on four continents. Specializing in custom thick film heating and resistance products, TFT has supplied products to the Aerospace, Industrial, Medical, Consumer and Research sectors.

OUR CLIENTS LOVE US

-

We worked with the crew at Thick Film on a few different projects over the period of two years and found them to be creative problems solvers, responsive to our needs and concerns and professional in every way. We would use their services again and would recommend them to others needing their services

Dan Briscoe, Vice President, Apollo Sensor Technology -

We enjoy working with TFT because they are very responsive to technical inquiries and are proactive in finding solutions to design challenges, even ones that we have not foreseen — TFT has always made me feel that we are working together on the same team. In addition, they are very conscientious about delivery time and the end product is of very high quality.

Neil Dilley, Ph.D, Applications Physicist, Quantum Design, Inc. -

We have worked with the team at Thick Film Technologies on several international consulting projects and have found them to be professional, responsive and effective. We intend to maintain and expand our relationship and would not hesitate recommending them to anyone.

Ken Kuang, President, Torrey Hills Technologies, LLC

PASSION FOR DESIGN

“Whether it's creating a new product, improving on a legacy or creating the tools needed to enable research into new science, we know our customers have the passion for design. We hear it in their voices and we see it in the innovative and challenging projects they present to us. Every day we are privileged to work with brilliant engineers and scientists solving interesting problems, we know they have a passion for design, because we have it too.”

-Kirk Goldenberger, President, Thick Film Technologies Inc.