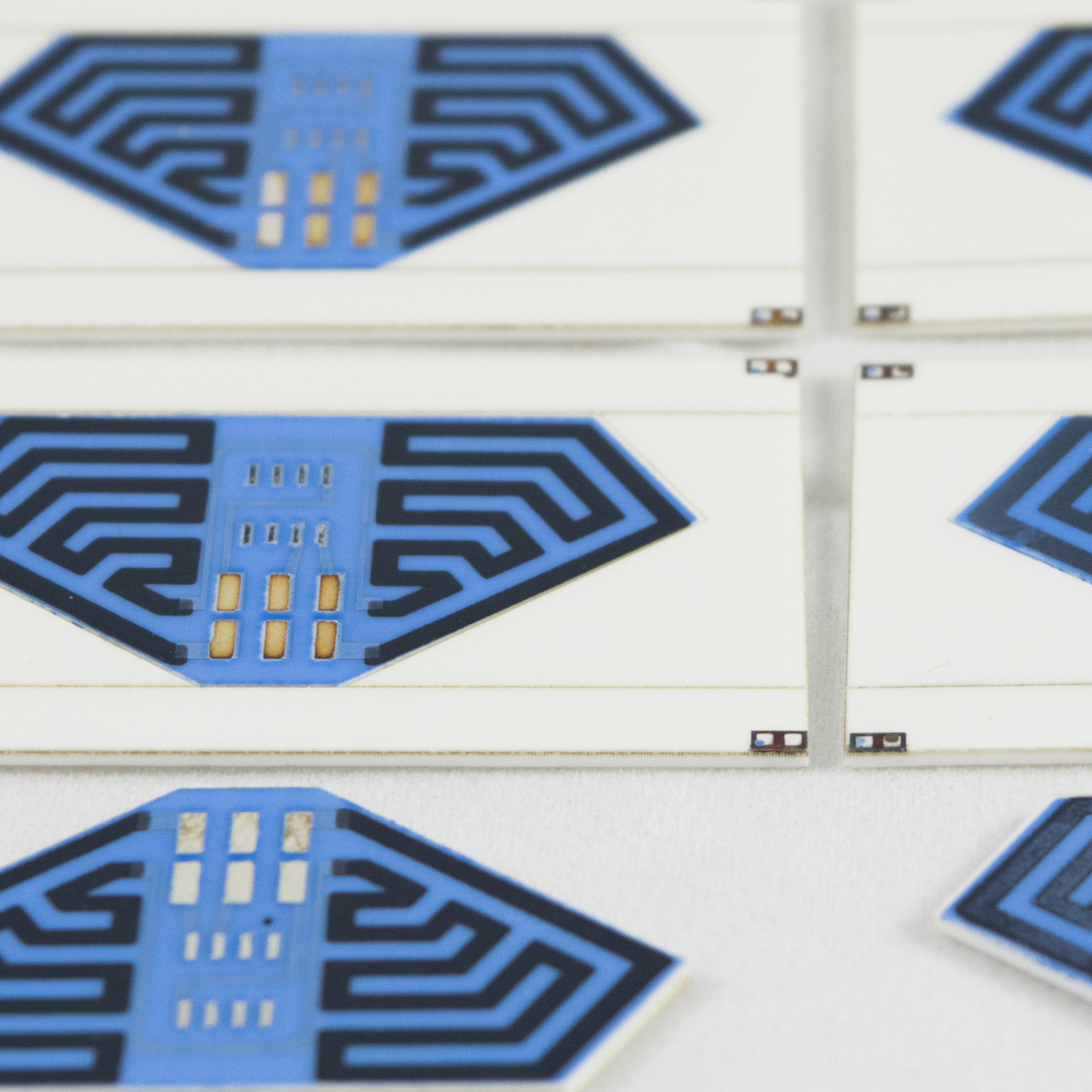

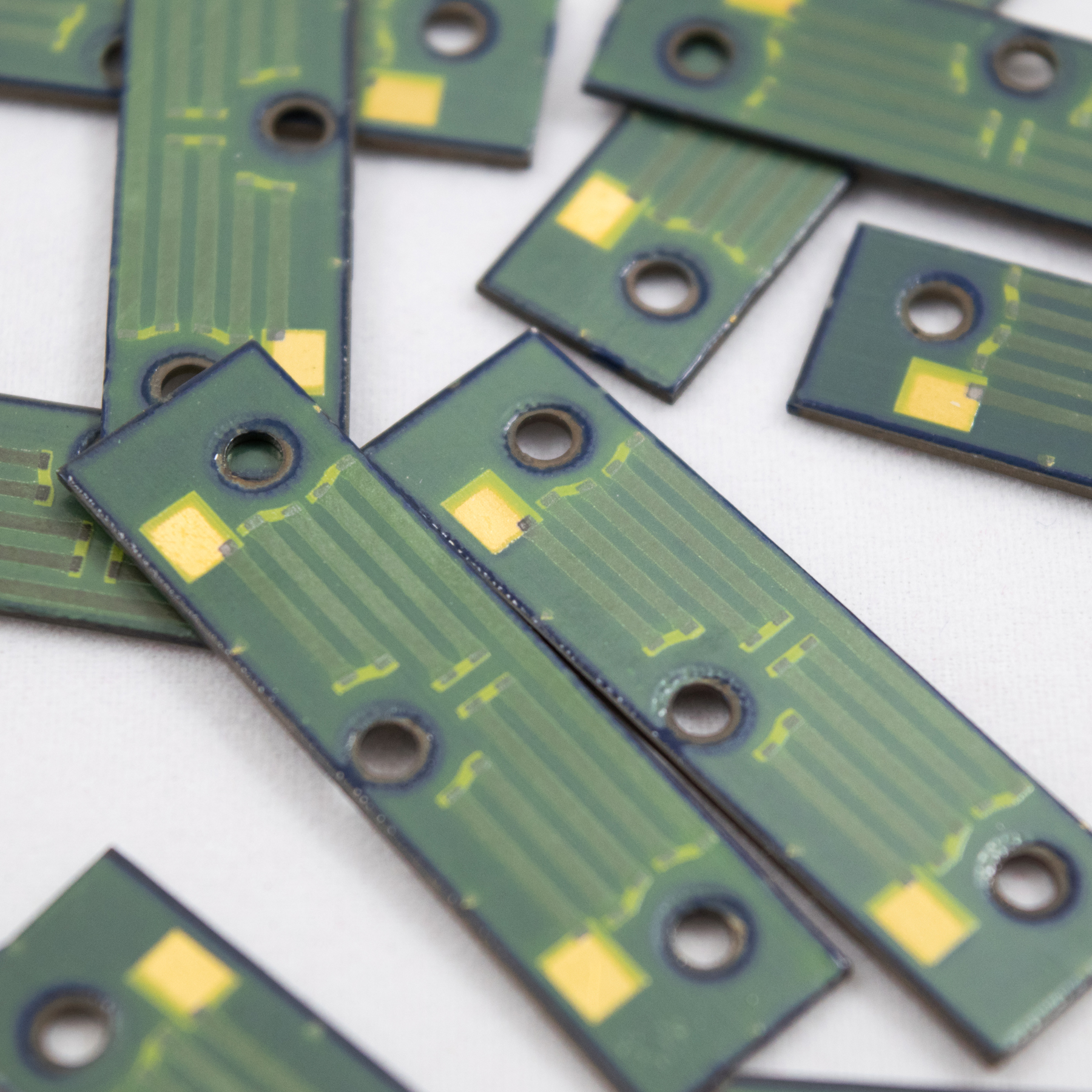

In 2014, An FAA certified repair depot was looking for a supplier of heating elements for a specific piece of aviation Galley equipment used on a wide range of airliners. The cost to replace the galley equipment is very high and airlines often choose rebuilt rather than new equipment to reduce cost. The OEM closely controlled the supply lines of the specialty heating elements driving up the cost of replacement parts and making it difficult for repair depots to compete. The airlines wanted more choices in where they could purchase rebuilt galley equipment with performance and lifetime at least equal to the OEM. The customer came to us and asked if we could reverse engineer the original heating element, and develop a custom designed drop-in replacement that could pass all the FAA testing requirements. We worked with the customer and created a laser cut ceramic heater with improved solder joints and potting characteristics that meets or exceeds the OEM performance.